While deciding on a steam boiler for your business, it can be complex and important. It may enhance the efficiency of the process while reducing costs if the right boiler is used to meet all specific needs of operation. With several options available from different industrial steam boiler manufacturers, one really has to make an informed choice. We will explore in this blog some key considerations in choosing the right steam boiler for your business needs.

1. Understand Your Steam Requirements

The first step in choosing a steam boiler is to clearly understand the steam requirements for your business. This includes:

Capacity Needs: Find out how much steam your processes would need. Normally, it is measured in pounds per hour (PPH) or kilograms per hour (kg/h). Consider peak and average steam demand to make sure that the boiler has the ability to keep up with the fluctuations of the usage.

Pressure Requirements: Specify the pressure at which the steam to be conveyed is required. Applications differ and so do pressure requirements, and the selection of a boiler bearing such a qualification is primary in choosing.

Steam Quality: The application may demand the quality of the steam to be superheated or saturated. Let the intended application define your choice of boiler with regard to the steam quality expected.

2. Types of Steam Boilers

There exist several types of steam boilers, along with the associated advantages and limitations. Major ones include the following ones:

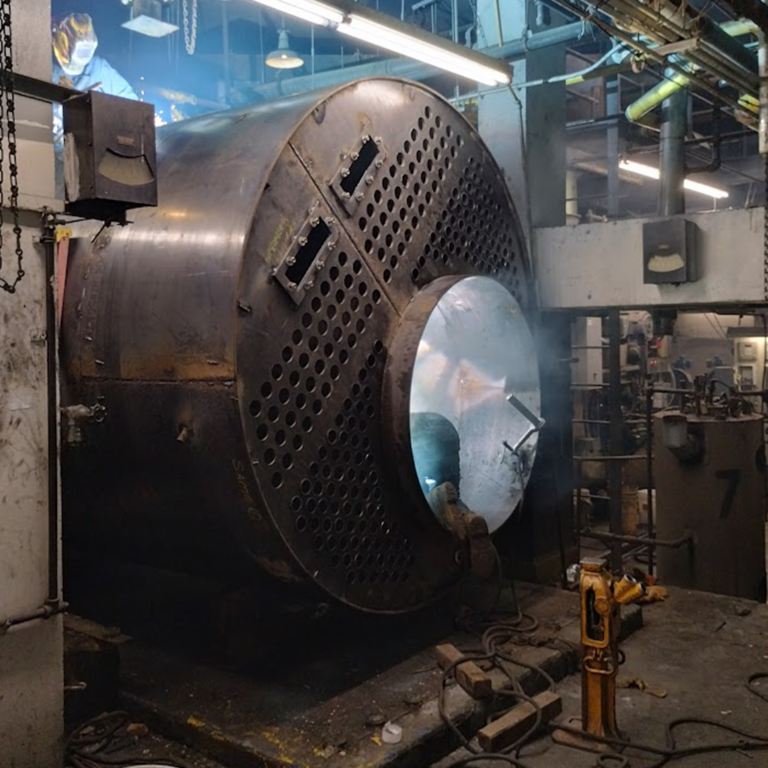

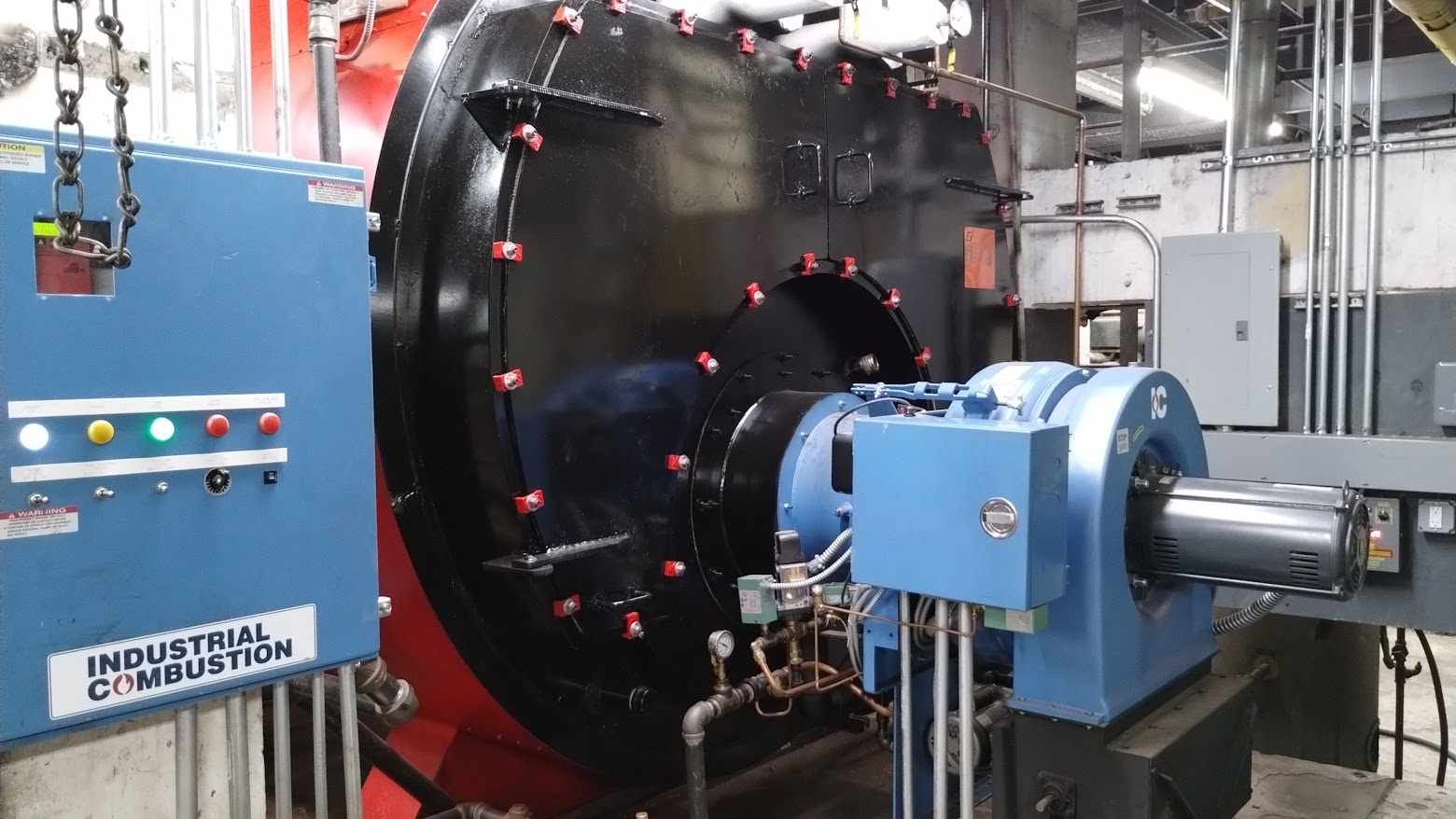

Fire-tube Boilers: In these, there will be the flow of hot gases through tubes surrounded by water. These boilers are useful for low to medium pressure uses. Moreover, fire tube boilers can be easily handled and serviced.

Water-tube boilers: Water runs through tubes that are externally heated by hot gases. They are very good for applications of high pressure and mostly used in industries that require lots of steam.

Electric Boilers: Electric boilers basically rely on electricity for the generation of steam and are commonly used for small-scale applications or areas where their primary energy source is electricity.

Condensing Boilers: These are of high efficiency and involve the recovery of heat in the flue gases, which prevents them from getting wasted. They can find applications in areas where there is a huge energy efficiency requirement.

With this knowledge of boilers, their types, and differences, one is better placed to select which boiler to use for a particular need.

3. Fuel Source

One also needs to consider the fuel choice. A broad spectrum of fuels used in steam boilers includes:

Natural Gas: Widely used because of availability and its relatively low cost. It is also cleaner burning compared to other fossil fuel alternatives

Oil: Popular choice where natural gas is not available to be used for heating of the oil-fired boiler. Oil-fired boilers can run on diesel, heavy oil or other types of oil.

Coal: Today it's not widely used due to environmental concerns, but for industries that have access to coal that is reasonably priced, the coal-fired boilers are a good choice.

Electricity: Electric boilers are applicable in institutions where emissions are an issue or electricity is the cheapest source of energy.

Biomass: Working by burning organic materials such as wood chips, agricultural waste, or pellets, these boilers are an environmentally friendly solution, more particularly for companies with strong concerns and goals about sustainability.

The right fuel will be chosen according to availability, cost, and environmental regulations in your area, together with the set sustainability objectives of the company.

4. Efficiency and Emissions

Efficiency is important in that it will involve direct operating costs. Seek high thermal efficiency ratings, which describe how well the boiler converts fuel into steam. Condensing boilers may have ratings above 90%.

Apart from the efficiency, consider the emission of the boiler. Most jurisdictions regulate emission rather strictly, and the choice one should go for should be within these standards. The modern boilers have a variety of emission control technologies to help reduce pollutants. The usual ones are low NOx burners and flue gas recirculation.

5. Space and Installation Considerations

This will depend on the available physical space for the boiler and complexity of installation. While there are those boilers that require more space for installation and maintenance, others are compact. Consider layout of your facility and accessibility to it for maintenance when choosing a boiler.

Also, the installation process itself may differ in complexity and, accordingly, cost. Some boilers require extensive piping and auxiliary equipment, which adds to both the overall installation time and expense.

6. Maintenance and Reliability

The reliability and easiness of boiler maintenance are critical to reduce downtime and ensure continuous hassle-free operations. Look for boilers with a good record of reliability and those that have relatively easy maintenance.

Check if replacement parts are easily available and what level of support is provided by the manufacturer or supplier. For instance, top manufacturers of industrial steam boilers offer great customer support and spare parts can easily be accessed.

7. Cost Considerations

While the initial cost of purchase is an essential factor in purchasing a boiler, it is not the only important factor. The overall cost of owning a boiler should be considered. This includes:

Fuel Costs: Fuel cost is a major item of operating expense. The boiler to be selected should be fired with the most economical and readily available fuel in an area.

Maintenance Costs: Consider the expenses of periodic maintenance, repairs, and replacement of parts.

Installation Costs: Consider the installation cost, including modification to a facility, if required.

Where efficiency savings may justify a higher capital outlay: A more efficient boiler will have higher capital costs but lower fuel costs in the long run.

8. Conformity with Regulations and Safety

Use a boiler that meets all the major safety standards and regulations. Such standards and regulations shall include, but not be limited to, the local, state, and federal requirements for boiler operation, emissions, and safety. Obviously, compliance is necessary from both a legal and practical point of view: safety for your employees and the community around.

9. Customization and Future Needs

Check if this boiler is customizable to suit your exact needs. Some manufacturers can configure, add features, or upgrade boilers for better performance.

Also consider the future needs of your company. If growth or change within the steam requirements is foreseen, select one that can be easily upgraded or expanded.

10. Manufacturer's reputation and reviews

Finally, consider the reputation and reviews of the industrial steam boiler manufacturers you are considering. Look for manufacturers that have solid reputations for quality in the products produced and their reliability, besides customer service. You can learn much about a product's actual performance and reliability, and the amount of support offered by the manufacturer from reading reviews or testimonials by other businesses.

Discover Top-Quality Boilers from Supreme Boilers

When selecting the perfect steam boiler for your business, consider the comprehensive range of products offered by Supreme Boilers. Renowned for their quality and reliability, Supreme Boilers provides a variety of boiler series to meet diverse industrial needs. The Oil Series is perfect for operations requiring oil-fired systems, while the EASCO SM4 Series and EASCO SM5 Series offer robust solutions for different steam capacities and pressures. For businesses prioritizing efficiency, the EASCO PLW Series and EASCO ESP Series feature high-efficiency designs, including options for waste heat recovery. Additionally, the EASCO FPS Series provides flexible and compact solutions ideal for various applications. With Supreme Boilers, you're assured of exceptional products that cater to your specific requirements, backed by outstanding customer support.

Conclusion

The correct choice of a steam boiler for a business demands that one needs to carefully consider a number of aspects. These would include your steam requirements, fuel source, efficiency, emissions, maintenance, and other associated costs. Clearly assessing the needs and the weighing of options available takes time to select a boiler for exactly what one wants, ensuring years of reliable and efficient service.

A rightly chosen boiler is something of an investment in productivity and sustainability for your business. With the right information and proper consultation, you can make an informed decision that will benefit your company both now and in the future.

Write a comment ...