Steam boilers play a critical role in both commercial and industrial settings by generating steam for heating, processing, and power generation. However, not all steam boilers are created equal. The demands of a hospital’s heating system differ significantly from those of a large-scale food processing plant or refinery. Understanding the key differences between industrial steam boilers and commercial steam boilers is essential for facility managers, engineers, and business owners who are considering boiler installation, upgrade, or replacement.

In this comprehensive guide, we’ll explore what distinguishes industrial steam boilers from commercial ones in terms of capacity, design, performance, application, and regulatory requirements. By the end, you’ll have a clear understanding of which type of boiler is right for your facility and how to make the best choice for long-term reliability and efficiency.

What Is a Commercial Steam Boiler?

Commercial steam boilers are typically used in businesses, institutions, or facilities that require low to medium-pressure steam for heating or light process applications. Common examples include office buildings, schools, hospitals, apartment complexes, and small-scale food production units.

These systems are often compact and designed for easy integration into building mechanical rooms. They operate at relatively moderate steam pressures—usually below 15 psi for low-pressure applications—and offer a balanced combination of performance, size, and efficiency.

Commercial boilers prioritize user-friendly interfaces, simplified maintenance, and cost-effective operation. They’re also usually built with modularity in mind, allowing facilities to expand capacity by adding additional units as needed.

What Is an Industrial Steam Boiler?

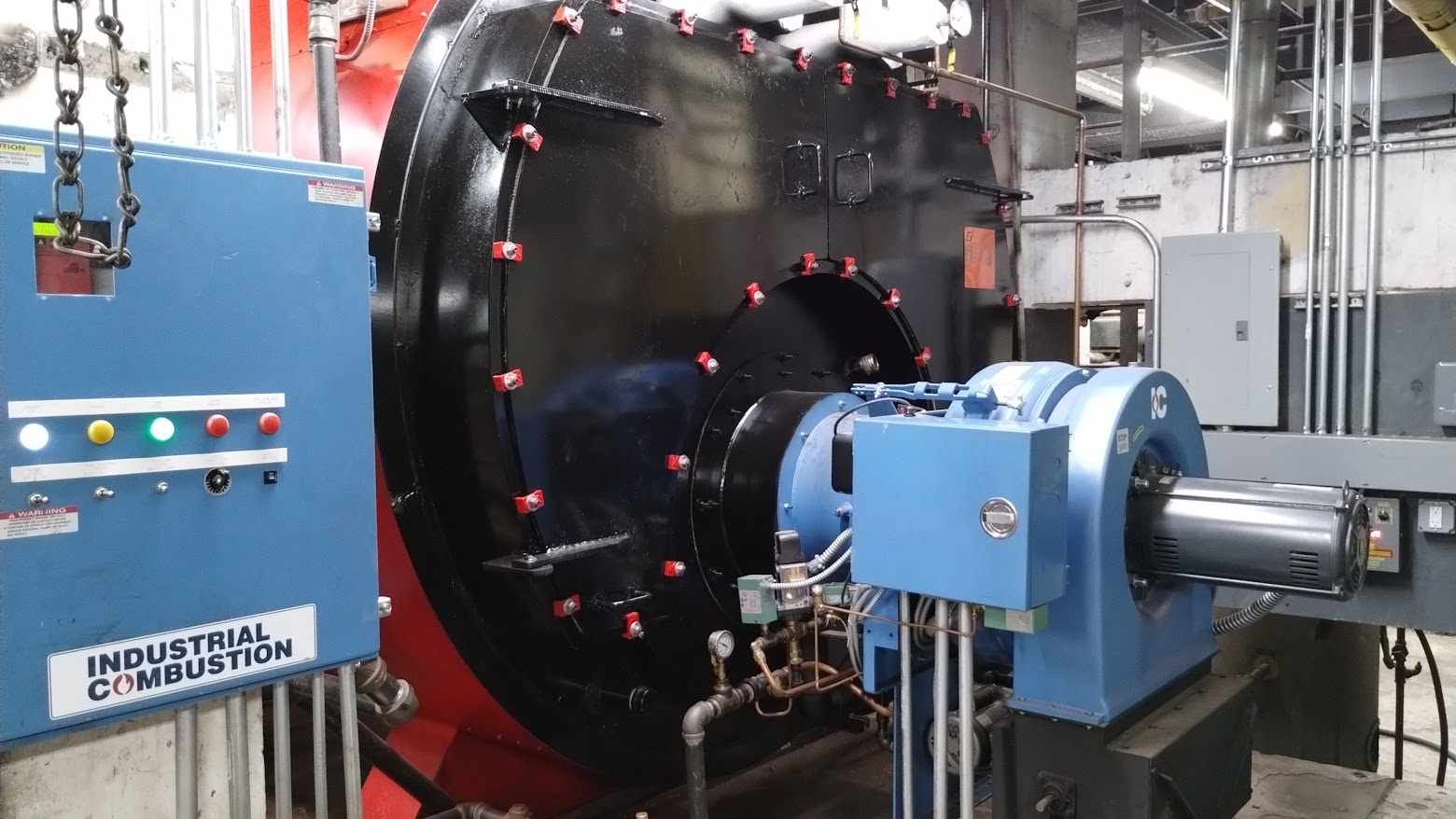

Industrial steam boilers, on the other hand, are engineered for high-performance applications in manufacturing, chemical processing, pharmaceuticals, refineries, food and beverage production, and other heavy industries. These systems are built to handle demanding operational environments, often running 24/7 and producing steam at pressures exceeding 150 psi, with some systems reaching well beyond 1,000 psi.

Unlike their commercial counterparts, industrial boilers are usually customized to meet specific process requirements. They are larger, more robust, and built from heavy-duty materials to withstand extreme pressures, temperatures, and operating cycles.

These systems may include advanced controls, economizers, heat recovery systems, and integration with other plant equipment. Safety, durability, and fuel efficiency are top priorities for industrial steam boiler design and implementation.

Key Differences Between Industrial and Commercial Steam Boilers

Although both types of boilers share the same basic function—producing steam—their operational scope and engineering vary in important ways. Let’s dive into the core differences:

1. Steam Pressure and Temperature

Commercial boilers are typically low-pressure systems designed for comfort heating and light-duty steam applications. They rarely operate beyond 15 psi of steam pressure. This makes them easier to install and manage, and generally subject to less stringent regulations.

In contrast, industrial steam boilers operate at significantly higher pressures, often starting at 150 psi and reaching up to several hundred psi depending on the application. High-pressure steam is essential for driving turbines, sterilizing equipment, and conducting heavy-duty processing tasks.

Along with higher pressure comes higher steam temperatures. Industrial systems must be built to withstand these extreme conditions over extended periods.

2. Design Complexity and Size

Commercial boilers are usually packaged units that are relatively small and simple in design. They often come as firetube systems that are compact and easy to service.

Industrial boilers can be much more complex. While firetube designs are still used in some industrial contexts, watertube boilers are more common due to their ability to handle high-pressure applications and fast load changes. Watertube boilers circulate water through tubes heated externally by combustion gases—a design that’s well-suited for continuous operation and high heat transfer efficiency.

Industrial systems also involve additional components like superheaters, deaerators, economizers, and advanced control panels, all of which require more space and specialized maintenance expertise.

3. Capacity and Output

Commercial steam boilers are designed to produce a limited volume of steam, often ranging from a few hundred pounds to a few thousand pounds per hour. This is sufficient for smaller facilities that need steam for HVAC systems or light-duty equipment.

Industrial steam boilers are significantly more powerful. They are capable of producing hundreds of thousands of pounds of steam per hour to support large-scale processes. Their fuel consumption, water treatment systems, and steam output are all scaled for continuous, high-capacity operation.

The higher output not only demands sturdier construction but also requires a robust fuel delivery and emissions management system.

4. Applications

The practical usage of the two boiler types further clarifies their differences.

Commercial steam boilers are commonly found in hospitals (for sterilization and space heating), universities, commercial laundries, and hotels. In these environments, consistent but relatively low levels of steam are required to maintain operations.

Industrial steam boilers serve sectors like oil and gas, food processing, chemicals, pulp and paper, and power generation. In these industries, steam may be used to drive mechanical turbines, sterilize equipment, heat raw materials, or act as a reactant in a chemical process.

Because the cost of downtime in industrial settings is extremely high, industrial boilers are built with redundancies, fail-safes, and advanced diagnostics to ensure uptime and reliability.

5. Regulatory and Safety Requirements

Due to their smaller size and lower pressure, commercial boilers generally fall under less stringent regulatory oversight. However, they still must comply with local building codes, emissions standards, and boiler inspection laws.

Industrial boilers, due to their complexity and risk profile, are subject to a much more rigorous set of regulations. These include national codes such as the ASME Boiler and Pressure Vessel Code, as well as environmental standards from the EPA or equivalent agencies. Regular inspection, certification, and compliance audits are mandatory.

Training for operators is also more demanding. While commercial boiler operators may only need basic certification, industrial boiler operators must often undergo extensive training and obtain specialized licenses.

Choosing the Right Boiler for Your Facility

If you’re in the market for a steam boiler, your decision should be guided by your facility’s size, steam demands, operational hours, and safety requirements.

Small- to mid-sized operations that require consistent heating and basic steam capabilities will likely find a commercial boiler to be the most cost-effective and manageable option. They are easier to install, simpler to maintain, and well-suited to HVAC or small process needs.

However, for manufacturing plants, refineries, or any facility where steam is integral to the core business operation, an industrial steam boiler is not just a better fit—it’s essential. Industrial systems are built for performance, durability, and scalability. Although they require a higher initial investment, their efficiency, capacity, and reliability provide substantial long-term value.

Supreme Boilers: Commercial and Industrial Excellence

Whether you need a rugged industrial system or a dependable commercial unit, Supreme Boilers offers high-efficiency steam boiler solutions tailored to your needs. Their product lineup covers both ends of the spectrum with precision-engineered systems built for maximum performance and fuel savings.

For commercial applications, the FPS Series and FST Series provide compact, firetube designs perfect for schools, offices, and healthcare facilities. These systems deliver reliable steam with minimal maintenance and strong thermal efficiency.

In industrial environments, Supreme’s ESP Series and PLW Series stand out for their high-pressure watertube configurations and rugged build, making them ideal for continuous operations in tough industries. Their premium SM4 Series and SM5 Series feature advanced control systems, superior combustion technology, and unmatched durability—ensuring energy savings and uptime even under extreme conditions.

Backed by expert technical support and a reputation for excellence, Supreme Boilers offers customized solutions for both commercial and industrial steam needs.

Final Thoughts

Choosing between an industrial and commercial steam boiler is not just a matter of scale—it’s about aligning your boiler system with the unique needs of your operation. While both serve the purpose of producing steam, they differ greatly in terms of pressure ratings, capacity, durability, and application scope.

A commercial steam boiler may offer simplicity and affordability for smaller operations, but when reliability, volume, and high-pressure output are critical, an industrial boiler becomes indispensable.

No matter your steam requirements, selecting the right boiler will directly impact your energy efficiency, maintenance costs, and operational success.

Write a comment ...