In full-scale industries the two pillars that uphold success are: efficiency and reliability. Nothing in this category expounds this better than advanced boiler technology. EASCO SM4 Series happens to be one of the most recognized designs displaying a good balance between ruggedness and service performance. Used in a variety of heating applications, this boiler embodies the culinary art of science in the business of energy conservation, emissions reduction, and steam delivery with consistent quality.

In practice, industries rely upon a set-point heat in power production, but we can say, these boilers work well in generating heat with high outputs at economic fuel rates. They undergo various loading demands without showing out under trying conditions. A combination of old designs with no priority to fuel flexibility or emission control, and the new designs setting the new pace for cleanheat and operational excellence, really paves the way in this direction.

How Did Boiler Design Evolve to Meet Modern Efficiency Standards?

The metamorphosis of the boiler technology in the years is a critical question. From a mere heater or water generator, a boiler has evolved as one of the most valued machines that constitute the milieu of thermodynamics fused with engineer-pragmatical components. No time for waste heat and combustion control technology, and insulation (making the fuel rates worth paying): Boilers and technology had changed forever.

The global ecological context was another driver in the design process: With increasing international legislation limiting carbon concentration, boilers, in their latest manifestations, were equipped with low-NOx burners and heat recovery systems. Throughout, the modern models have been considered structurally intact for long-time operation using suitable, rugged materials and the finest manufacturing practices.

Why Is Automation Critical in Modern Furnace Boilers?

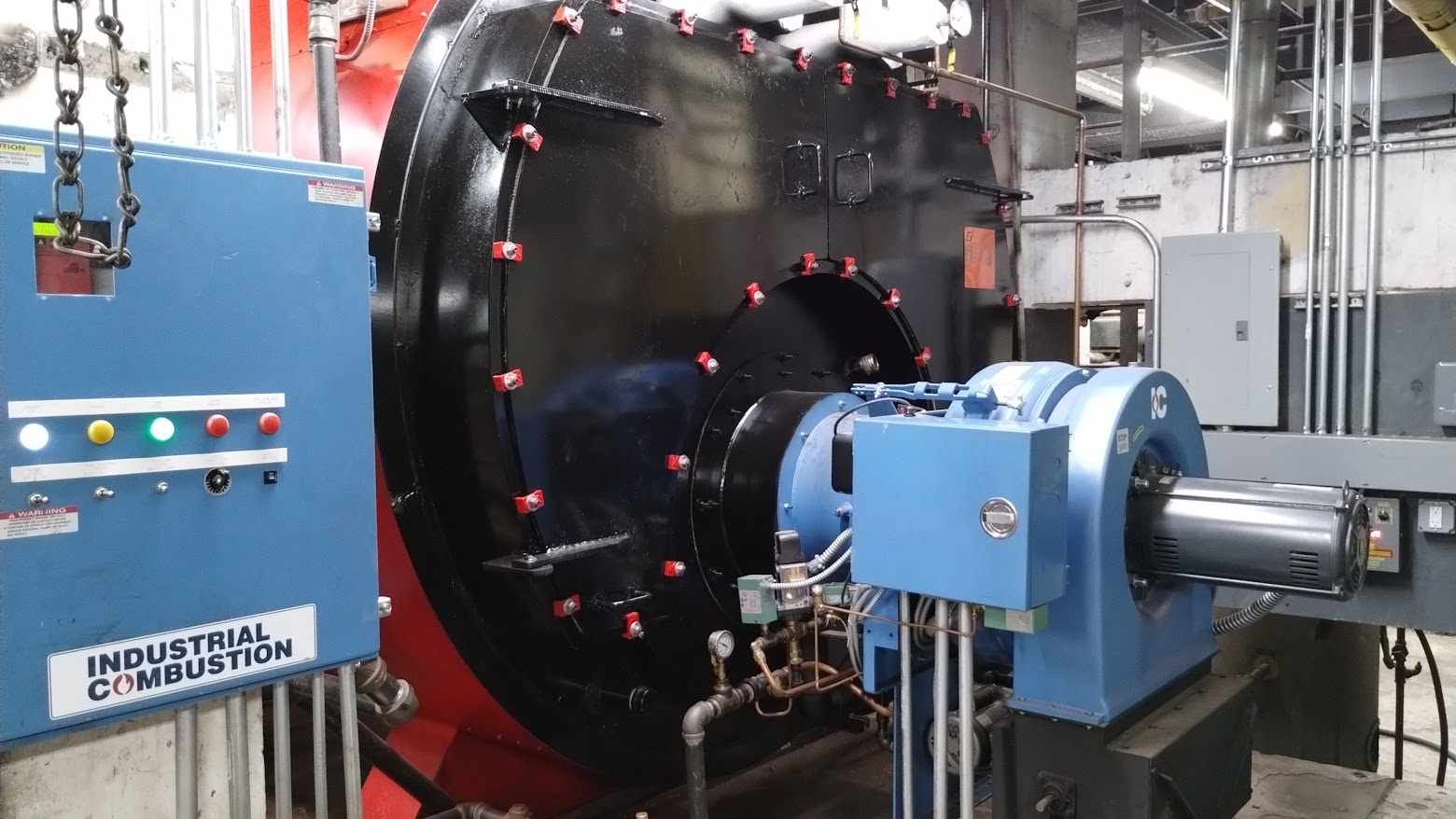

Automation is a critical player among the array of vital features in the peripheral discourse of a modern boiler. Control systems have enabled abilities that static equipment could never plot against. Boilers now have a comprehensive set of control systems. For the first time, boiler operators are able to monitor in real-time actual temperature, pressure, and efficiency parameters to regulate toward greater performance without compromising safety. This increased digitalization has worked in minimizing downtime and has made possible the concept of predictive maintenance, which in one way or another reduces the risk of incurring significant pecuniary loss.

So, efficiency is the heart of industrial heat production.

For steam or hot water-generating plants, energy costs are among their highest cost items. High-efficiency boilers represent a key lever in cost-containment and in sustainability. They generally benefit from very high thermal performance. The logic behind fuel utilization is to distribute the maximum possible proportion of energy input into useful heat in the boiler. In such conditions, the design of the boiler application is a strong virtuous loop vis-a-vis its strength to employ the highest fuel-side efficiency while keeping the combustion output-to-energy conversion in balance with useful heat production.

Very often, one boiler can adjust to multi-fuel capabilities, so that industries can switch between gas, oil, or renewable fuel sources, according to their price and availability. This way, these boilers promise increased flexibility to move away from fuel availability to economic returns. Advanced insulation encompassed with very high heat retention ensures minimal energy ensues presenting great advantage while in actual operation.

Efficiency is not about numbers; it is about a long-term impact. They are energy gobblers; the less energy they consume, the more they help with reduced emissions and lessening carbon footprints in line with global sustainability goals. Even industries under regulatory scrutiny get reprieve with a mores efficient boiler system in the sense that power supply will better them in one way and reduce cost simultaneously.

Different Boilers for Differing Industrial Needs

Hardly any two industrial environments and heating requirements were ever the same. Some are concerned about steam output, others about compactness, others yet about low emissions. For example, SM5 Series follows on the same design route modified to serve within slightly different performance preferences and operating scales. Each series in the product catalog addresses a different need and calls for versatility such as chemical processing, food production, or power production.

In an industrial application, flexibility design allows the configurations that define an energy strategy. Whether high-pressure steam turbines or low-pressure outputs for heating systems render to specific process operations—modern boilers offer tailored solutions. The flexibility practically guarantees that every unit will perform all day long, regardless of environmental conditions, largely by dampening their graceful performances when confronted with load variations.

Why then do boilers occupy the countless roads to industrial progression?

Boilers are an essential cog in a wheel because industry need ever-greater degrees of energy efficiency, safety, and environmental responsibility, each defining an epoch of industrial revolution with the ethical use of energy. The future may well be a playground for more digital ideas in the name of complete remote access, co-combustion solutions, and the integration into a smart grid—all these are solid signatures to boost the boilers' role in industrial infrastructural development.

Modernism is underway through the history of modern boiler technology. This literally sends us from enhanced thermal efficiency to better, intelligent control—parading all modern science in the exercise of energy management. The forward path toward industrial progress in some ways will be maintained by the greater advancement in the turbines of the industrial boilers.

Write a comment ...